The SuperESCA endstation

Just started..

Just started..

The SGM3 endstation

Your browser does not support viewing this document. Click here to download the document.

- A new Si-chamber has been added to the Preparation chamber on the SGM3 endstation. This extension allows for the cleaning of Si surfaces via resistive heating and it is equipped with evaporators and gas-lines specifically for 𝛿-layers preparation. In collaboration with Prof. Jill Miwa

The Quasi-chamber

It is finished! Info soon availlable

It is finished! Info soon availlable

Postdoc Projects

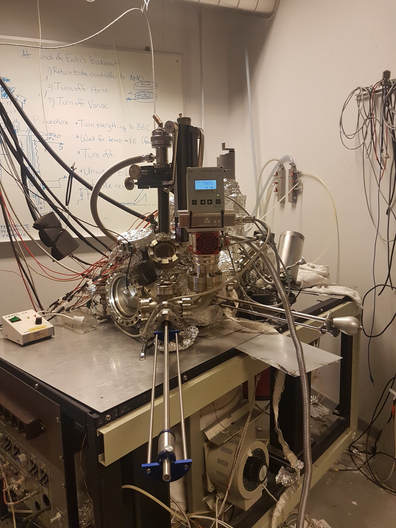

SGM3 endstation on a standard, messy, late-night beamtime

SGM3 endstation on a standard, messy, late-night beamtime

These projects have been realized together with the engineers, the design team and the technical workshop at the department of Physics and Astronomy and the ISA group. In particular John Erik Vad Andersen has to be acknowledged for his essential help giving technical suggestions and realizing (and checking) all the drawings, of which a few are presented here, while from the ISA group Hernik Kjeldsen and Søren Vronnig Hoffmann must be acknowledged for the design and commissioning of the new SGM3 beamline.

- Design, construction and commissioning of a multipourpose ARPES end station on the new SGM3 beamline @ ASTRID2

- Design, construction and commissioning of a low temperature 6 axis manipulator for ARPES

The project of this manipulator has been inspired by the group of Prof. Karsten Horn who we acknowledge for fruitful and useful discussions and collaboration.

These are two home made portable vacuum suitcases, battery driven, for Omicron and Aarhus plates. They allow for complete UHV transfer of samples between different facilities around the world. |

- The Graphene Factory

In this project i designed, constructed and commissioned a fully automated UHV chamber for graphene growth on different substrates and characterisation in UHV, called Graphene Factory (GF).

The work has been founded by the "DA-GATE" project (Danish Alliance of Graphene Application Technology).

The chamber is equipped with:

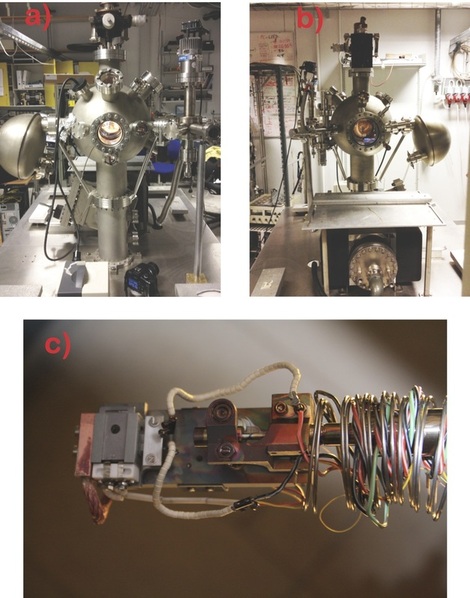

Fig. a) and b) show the GF from the viewport side and the LEED side, respectively. The Scienta single channel hemispherical analyser for AUGER spectroscopy is visible, together with the loadlock (on the right side of a)). The chamber aims to facilitate the iterative treatments for sample cleaning and CVD growth required to obtain high quality graphene. This is achieved using a simple user interface programmed in LabView by Maciek Dendzik and a fully automated and remotely controlled equipment. In Fig. c) is shown the manipulator head holding an empty sampleholder.

The work has been founded by the "DA-GATE" project (Danish Alliance of Graphene Application Technology).

The chamber is equipped with:

- Load Lock for fast load of samples in UHV;

- 5 degrees of freedom, liquid nitrogen cooled manipulator;

- automatic sputtering (up to 5 KeV);

- automatic annealing up to 1500 K (via hot filament, e-beam heating or resistive/direct heating);

- LEED;

- AUGER electron spectromiter;

- Si doser;

- Automated gas line with 3 remotely controlled leakvalves for CVD growth or chemical treatment and preparation (e.g. O2, H2, C2H4) ;

- O2 doser for local high pressure treatment (up to 0.01 mbar)

- RGA

- Pyrometer (for temperatures higher than 500 C)

Fig. a) and b) show the GF from the viewport side and the LEED side, respectively. The Scienta single channel hemispherical analyser for AUGER spectroscopy is visible, together with the loadlock (on the right side of a)). The chamber aims to facilitate the iterative treatments for sample cleaning and CVD growth required to obtain high quality graphene. This is achieved using a simple user interface programmed in LabView by Maciek Dendzik and a fully automated and remotely controlled equipment. In Fig. c) is shown the manipulator head holding an empty sampleholder.